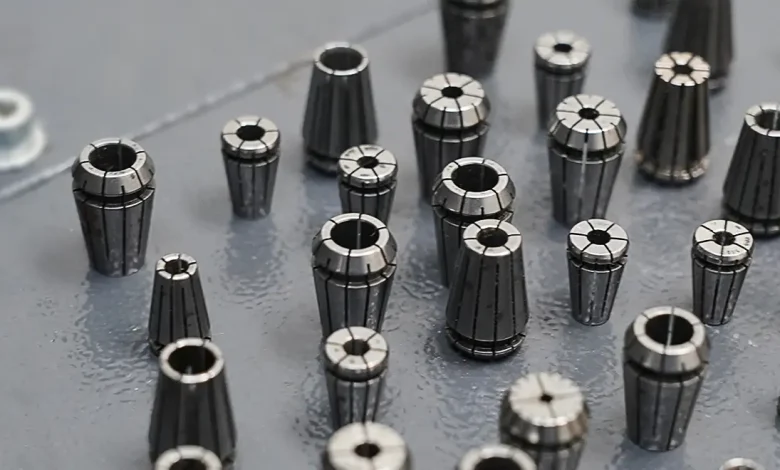

ER collet sets. The name may not be too exciting to say, but this small piece of hardware is important in the machining world. Choosing the right er collet set can transform a difficult task into a piece of cake, and the distinction between parts that fit snugly and parts that shake hands and run off in opposite directions. The strength of the collet is not taken seriously by people. However, for machinists who appreciate accuracy and efficiency, a critical selection will help them achieve high performance and reduce stress.

Start: the ER collet set is the substitute utility player of the gripping tools, be it drills, mills, or even reamers. It wraps your tool, keeping it fixed at an equal pressure. Slip anything less and you will find wobble, chatter, and runout. In plain words, your part will not fit, even though you bought the most expensive machine.

So, what should one look for when it comes to selecting the best set? The material is worth attention. Seized into solid steel at the top to last long and be flexible. Watch out when you hear of low-carbon steel or suspect alloy; otherwise, your wallet might go with you. Collets of this work out more quickly, lose their grip, or bend under pressure.

The process of getting things accurate silently creeps in at this step. Total indicated runout or TIR is something that must capture your attention. Think of TIR as the side-to-side sway of a dance. The smaller the better is your surface finish and tool life. Order sets of size less than 0.0004 in TIR measurement to get tight tolerances. Shops manufacturing aerospace components or medical components often swear by even tighter metrics.

The next puzzle is the size range.e Even though you might be tempted to buy the one-size-fits-all type of situation, ER collets are better simply because they are size-flexible. Collets are more of a money saver since each collet is a range of sizes (often 1mm or more). Be careful not to use more collets than you require, however, as they can be a real clutter in your desk and eventually a production bottleneck.

Do not disregard the closure nut. Some are balanced at high RPM, others are not. It makes the wrong one rattle your implement like a dog with a new toy. In addition, anti-slip grooves or threaded materials can feature a gliding rather than mousing action. That is better than wrestling with stuck nuts at work.

A bonus cleaning slide 2. The ease of cleaning slides was a surprising factor. Chips and dust adore cozying in collets, and dirt means poor toe-hold. Dullish surfaces, less number of crevices, and distinctive markings result in easy cleaning and quick identification of them. Picture yourself searching through the appropriate size, with the boss hovering above, about to scold you.

Brands are by no means the end of the story. Read reviews of users. To read of collets snapping open like eggs or holding like a vise. Occasionally, the off-brand gem is more effective, and another high-end name falls short.

Ask about compatibility as well. Some ER collett sets do not work harmoniously with every chuck. Take a second look at those numbers–ER16, ER32, ER40, etc. Fit matters. Collets with the perfect fit to your machine are the ones that are sized right to your spindle and holding needs.

Some funny? If you are thinking of saving with cheap collectibles, think of it: penny-wise pound-foolish. The bearings of precision spindles can become a nightmare of rattling door handles with low-cost bearings. Save your repair bill yourself.

Finally, storage. Good cases with labeled openings are said to keep your investment secure. Find one that will not encourage rust or allow collets to roll away to the land behind your bench to be lost forever.

The choice of ER collet set may be a matter of splitting hairs, but each detail makes the difference between success and failure on the shop floor. Take a couple of minutes on the front end and save yourself numerous minutes trying to track down tolerances, tool breaks, and the intensive use of curse words throughout the factory. Trick: understand what is important to your job. And that is the real secret of it–measured, tried, and true, by every machinist who ever saw a collet snatch him out of the jaws of death.

It tests new sets of doses through their runs so that they are not involved in production when they are yet to be fully tested. Test clamping force, check runout, and interchange tools to get a feel of any fouls. Follow your gut as well as specifications: sometimes there are only a few numbers on a datasheet compared to what you can feel in your hand. It is made of a reliable ER collet set, which becomes your unspoken assistant in precision.